RESEARCH WORK IN THE JOINT “3D MATTER MADE TO ORDER” CLUSTER OF EXCELLENCE OF HEIDELBERG UNIVERSITY AND THE KARLSRUHE INSTITUTE OF TECHNOLOGY

Lasers in today's generation of laser printers for paper printouts are very small. In contrast, devices that can print three-dimensional micro- and nanostructures still require large and expensive laser systems. Researchers at Heidelberg University and the Karlsruhe Institute of Technology (KIT) in the joint “3D Matter Made to Order” Cluster of Excellence (3DMM2O) are now using another process instead. So-called two-step absorption works with tiny, inexpensive blue laser diodes, making it possible to work with far more compact 3D printers. Researchers at the Centre for Advanced Materials at Ruperto Carola contributed substantially to the work. The results were published in the journal “Nature Photonics”.

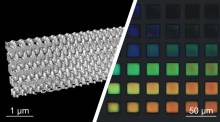

For additive manufacturing, 3D laser printing allowing for the best spatial resolution and extremely high printing speed is often the method of choice. In the process, a focussed laser beam is directed toward a light-sensitive liquid. At the focal point, the laser activates special molecules and triggers a chemical reaction, causing local hardening of the material. Any micro- and nanostructures can be produced by moving the focal point. So-called two-photon absorption triggers the reaction. Two photons, i.e. light particles, excite the molecule at the same time, causing the desired chemical change. Yet this requires complex pulsed laser systems, resulting in larger-size laser printers.

In contrast, the two-step process uses more compact and smaller printers. The first photon excites the molecule to an intermediate state, and the second photon brings about the desired end state, thus starting the chemical reaction. The advantage: This does not necessarily need to happen at the same time, like in two-photon absorption. As the study's first author, Vincent Hahn from the Institute of Applied Physics at KIT explains, compact and lower-power continuous-wave laser diodes can be used instead. However, this printing process requires specific photoresists, whose development took several years and was possible only in collaboration with chemists.

Reference Link:https://www.uni-heidelberg.de/en/newsroom/new-technology-for-compact-3d-laser-nanoprinters